What are VOCs in Floor Coatings?

Determining exactly what a VOC is only the first step of understanding VOC compliance. VOC regulations vary from state to state and are also construed differently based on the type of application. For example: a certain coating product may be acceptable for use in one state, but not the next. It also means that exact the same coating may be acceptable for use on and elevated steel beam but may not be used as a floor coating – even in the same building.

Determining exactly what a VOC is only the first step of understanding VOC compliance. VOC regulations vary from state to state and are also construed differently based on the type of application. For example: a certain coating product may be acceptable for use in one state, but not the next. It also means that exact the same coating may be acceptable for use on and elevated steel beam but may not be used as a floor coating – even in the same building.

VOCs are organic chemical compounds whose composition makes it possible for them to evaporate under normal indoor atmospheric conditions of temperature and pressure. They are described by the EPA as including a variety of chemicals (numbering in the thousands), some of which may have short and long-term adverse health effects.

Volatile organic compounds (VOCs) are emitted as gases from certain solids or liquids. Paints, coatings and varnishes all may contain organic solvents, as do many cleaning, disinfecting, cosmetic, degreasing and hobby products. All of these products can release organic compounds while you are using them, and when they are stored. VOCs are especially problematic when used indoors or in areas of limited ventilation. Concentrations of VOCs are consistently higher indoors (up to ten times higher) than outdoors.

The most common VOCs as it relates to resinous flooring products are found in solvents. Solvents include such chemicals as: xylene, acetone, toluene, ethyl acetate, MEK, and others. These solvents are designed to evaporate at room temperature at different rates depending on their intent. They are used to reduce the viscosity of the material (make it thinner) and also act as a carrying agent for resins as they penetrate a substrate, improving adhesion and extending working times.

How do VOC regulators define a Floor Coating? “An opaque coating that is labeled and formulated for application to flooring, including, but not limited to, decks, porches, steps, garage floors, and other horizontal surfaces, which may be subjected to foot traffic.”

How are VOCs Measured in the floor coatings industry? Within the paint & coatings industry, VOC’s are measured by the calculated mass of the VOC content relative to the overall volume of chemical. In most cases, this is represented as either grams/liter (g/l) or pounds per gallon (lbs./gal.).

VOC Regulations by Region

National and local regulators treat acceptable VOCs differently based on the application & industry.

Often referred to as “Intended Use Categories”, these applications include everything from Industrial High-Heat Coatings to Floor Coatings.

National & State VOC Rules

In the United States, the Environmental Protection Agency along with state and local authorities control the regulations for allowable VOC limits. Some individual states have their own requirements while others have collaborated based on their region to adopt regional multi-state statutes.

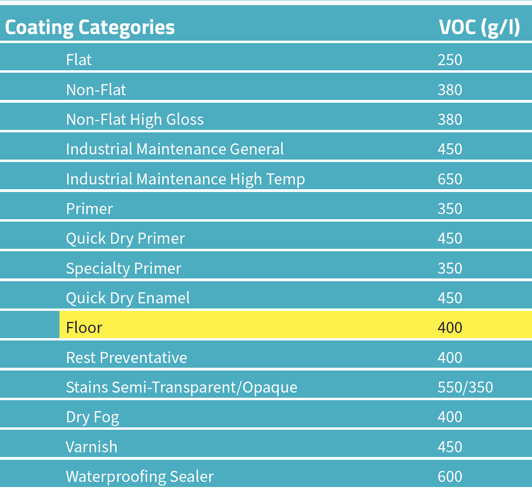

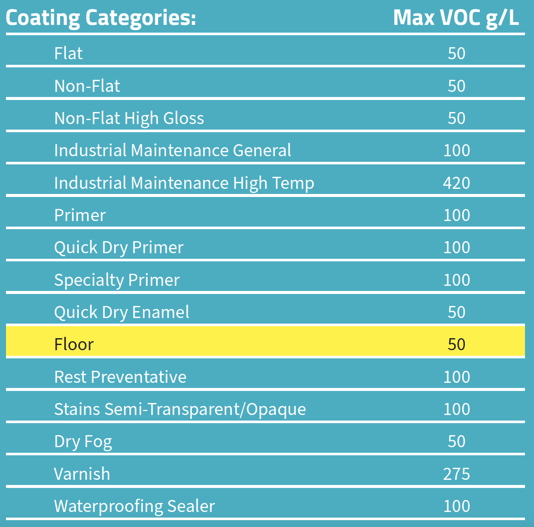

National AIM Rule

Coating manufacturers are limited in the number of VOCs that may be contained in their coatings by the EPA’sArchitectural Coating Rule for Volatile Organic Compounds. Enacted in 1998, this subset of the earlier Clean Air Act sets nationwide rules for the manufacture, labeling and packaging of coatings intended for use on any stationary structure. This rule is referred to as the National Industrial Architectural & Maintenance or “AIM” rule. The National AIM rule outlines the categories for coatings with corresponding VOC limits. The National AIM rule encompasses all US states and is the default rule for any states that do not have their own specific requirements. Other state regulations have largely followed the categories specified by the national AIM rule.

Coating manufacturers are limited in the number of VOCs that may be contained in their coatings by the EPA’sArchitectural Coating Rule for Volatile Organic Compounds. Enacted in 1998, this subset of the earlier Clean Air Act sets nationwide rules for the manufacture, labeling and packaging of coatings intended for use on any stationary structure. This rule is referred to as the National Industrial Architectural & Maintenance or “AIM” rule. The National AIM rule outlines the categories for coatings with corresponding VOC limits. The National AIM rule encompasses all US states and is the default rule for any states that do not have their own specific requirements. Other state regulations have largely followed the categories specified by the national AIM rule.

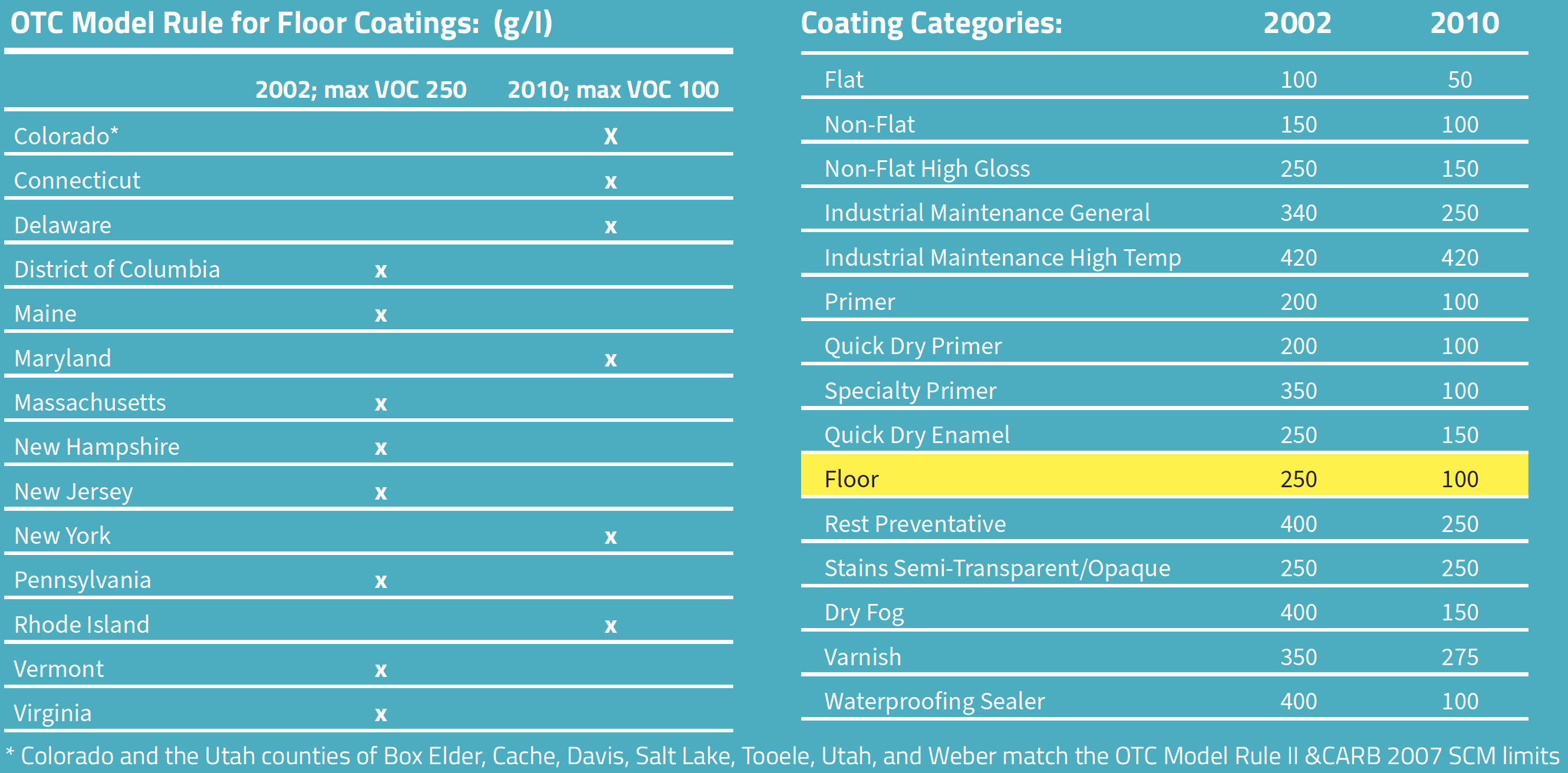

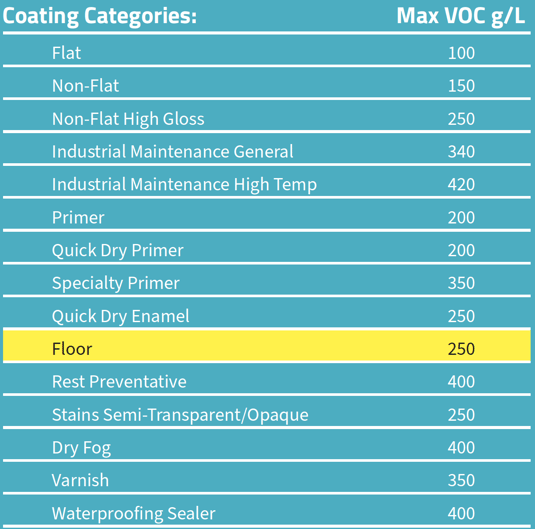

OTC Model Rule

The Ozone Transport Commission (OTC) is a multi-state organization created under the Clean Air Act to develop and implement regional solutions to the ground-level ozone problem and air quality in the Northeast and Mid-Atlantic regions. Currently, two model rules are available: Model Rule 2002 and Model Rule 2010. The two model rules provide for maximum allowable VOC content based on the coating category. Each participating state independently elects to adopt a model rule. All states have adopted Model Rule 2002 with the exception of Vermont which still follows the EPA National Rule and Virginia for which only select areas have adopted. Since 2017, several states have adopted Model Rule 2010 including Maryland, Delaware, Connecticut and Rhode Island. And, although Utah is not part of the OTC, it also has several counties that adopted Model Rule 2010, in 2015. The state of Colorado adopted OTC Model Rule 2010 in May of 2020.

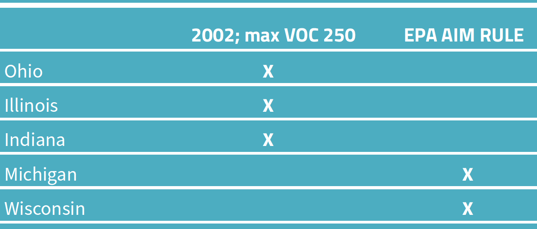

LADCO

Comprising the states of Illinois, Indiana, Michigan, Wisconsin, and Ohio, the Lake Michigan Air Directors Consortium (LADCO) was established to provide assistance and direction to the member states as it relates to air quality. Ohio, Illinois and Indiana have each adopted Architectural and Industrial Maintenance (AIM) coating VOC limits consistent with those in the OTC Model Rule 2002. Michigan and Wisconsin continue to follow the EPA National Rule.

Comprising the states of Illinois, Indiana, Michigan, Wisconsin, and Ohio, the Lake Michigan Air Directors Consortium (LADCO) was established to provide assistance and direction to the member states as it relates to air quality. Ohio, Illinois and Indiana have each adopted Architectural and Industrial Maintenance (AIM) coating VOC limits consistent with those in the OTC Model Rule 2002. Michigan and Wisconsin continue to follow the EPA National Rule.

CARB

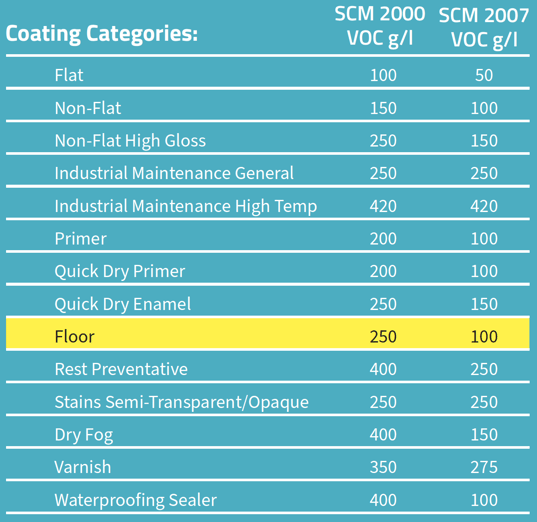

In 1967, the state of California established the California Air Resources Board (CARB) to oversee the activities of the now 35 local and regional air pollution control districts. It collaborated with those districts to develop air quality standards for several individual coating categories. In the early 2000’s, California amended the VOC limits for Architectural and Industrial Maintenance coatings via the Suggested Control Measures model rule. Most recently amended in 2007, the SCM provided guidance that has been adopted by some of the 35 individual air districts in the state of California. Some districts have implemented their own modified versions of the rule depending on their pollution requirements while others have remained under the National AIM guidelines. * Colorado and the Utah counties of Box Elder, Cache, Davis, Salt Lake, Tooele, Utah, and Weber parallel the CARB 2007 SCM limits.

In 1967, the state of California established the California Air Resources Board (CARB) to oversee the activities of the now 35 local and regional air pollution control districts. It collaborated with those districts to develop air quality standards for several individual coating categories. In the early 2000’s, California amended the VOC limits for Architectural and Industrial Maintenance coatings via the Suggested Control Measures model rule. Most recently amended in 2007, the SCM provided guidance that has been adopted by some of the 35 individual air districts in the state of California. Some districts have implemented their own modified versions of the rule depending on their pollution requirements while others have remained under the National AIM guidelines. * Colorado and the Utah counties of Box Elder, Cache, Davis, Salt Lake, Tooele, Utah, and Weber parallel the CARB 2007 SCM limits.

South Coast (SCAQM)

Since 1977, the South Coast Air Quality Management District has been regulating VOCs within California’s Orange County as well as the surrounding urban populations of Los Angeles, Riverside and San Bernardino counties.

Since 1977, the South Coast Air Quality Management District has been regulating VOCs within California’s Orange County as well as the surrounding urban populations of Los Angeles, Riverside and San Bernardino counties.

Often referred to as “South Coast” or “SCAMQD”, it has developed plans and regulations to bring compliance to federal and state clean air standards within this densely populated region. SCAMQD continues to have the most stringent VOC regulations in the nation.

Canadian VOC Regulations

On March 27, 2004, the Canadian government began developing regulations under Canadian Environmental Protection Act (CEPA) 1999 to set VOC emission limits. In October 2006, the Government of Canada outlined the approach to reduce emissions of air pollutants and committed to propose regulations limiting VOCs in consumer products.

On March 27, 2004, the Canadian government began developing regulations under Canadian Environmental Protection Act (CEPA) 1999 to set VOC emission limits. In October 2006, the Government of Canada outlined the approach to reduce emissions of air pollutants and committed to propose regulations limiting VOCs in consumer products.

The proposed VOC concentration limits have been developed to align with requirements in those U.S. states that are members of the Ozone Transport Commission (OTC).Implemented on September 9, 2010 , under the Canadian Environmental Protection Act, 1999 (CEPA 1999) these regulations provide VOC concentration limits coatings.