Superior Durability & Custom Finish

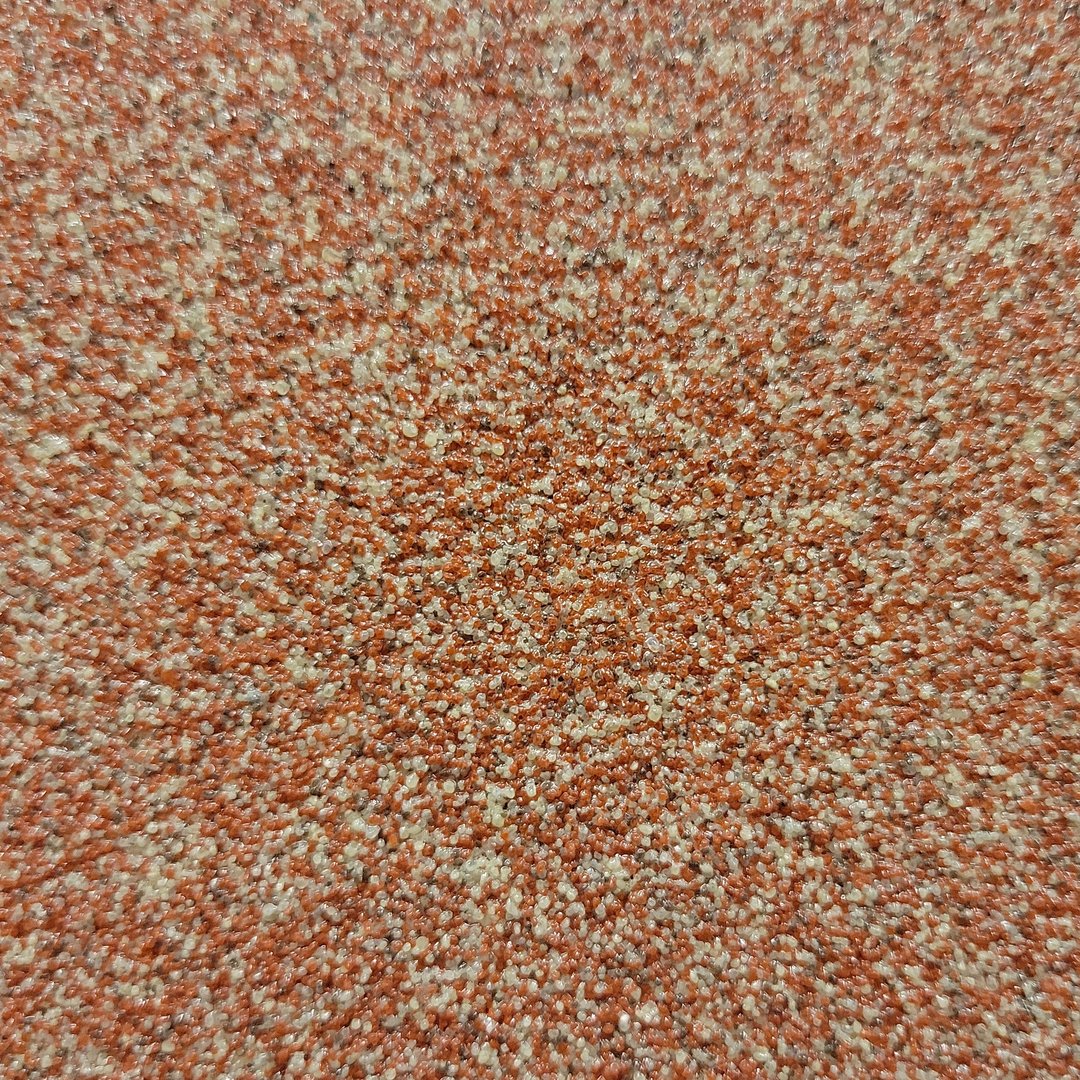

For high traffic environments, seamless quartz flooring systems are among the most widely used due to their superior durability. Colored quartz aggregates combine the elements of superior impact resistance, high traction and aesthetic appeal to create a floor coating that will stand the test of time. Owners have the capability to select from an infinite number of colored quartz blends to achieve whatever finish is required for their environment.

Quartz flooring systems are widely used in commercial applications and provide for a uniformly textured surface that offers increased traction where required. Resinwerks™ offers 8 standard quartz blends with the ability to custom blend and match as needed.

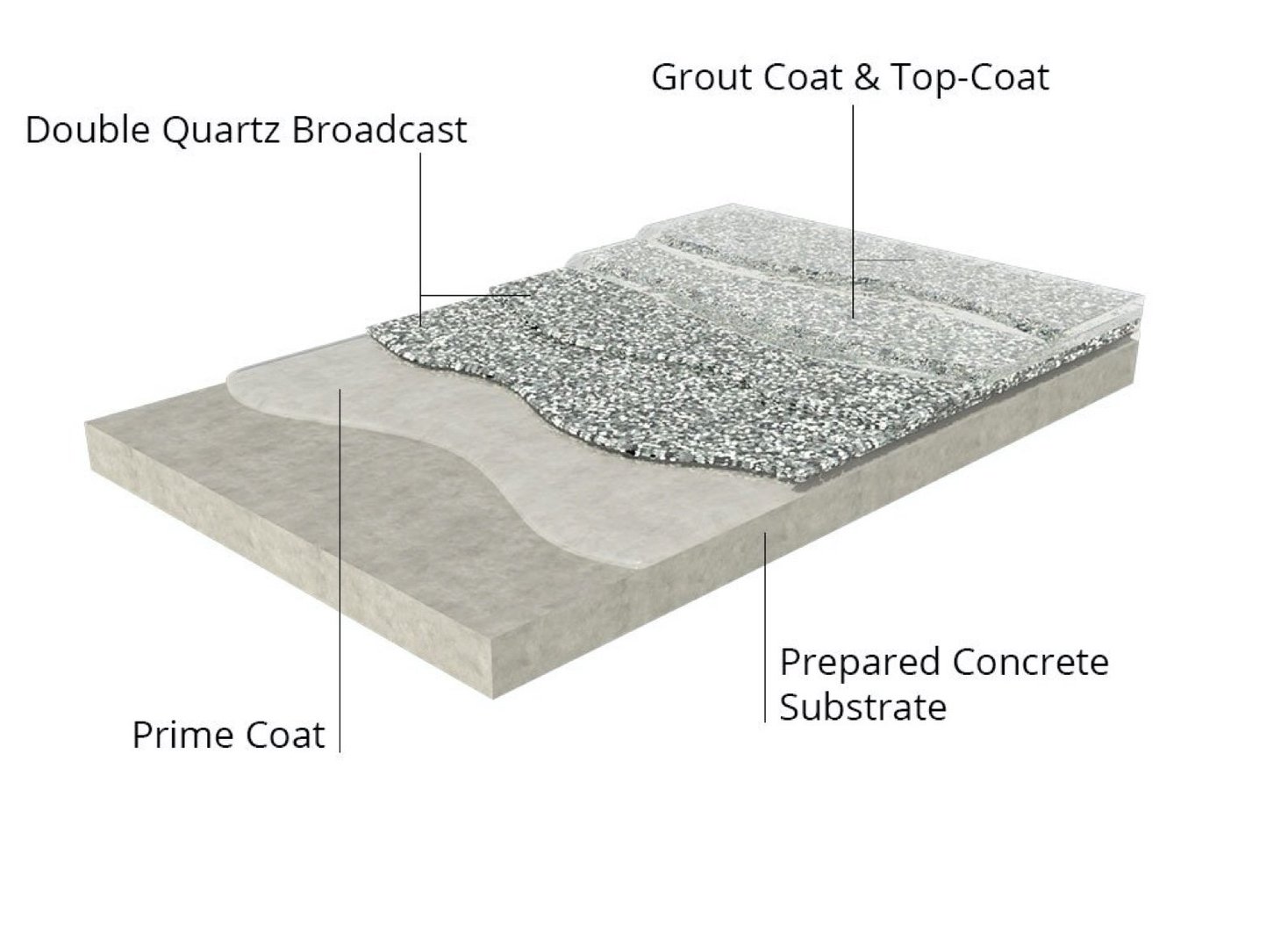

Quartz System Design

Quartz flooring systems incorporate extremely durable, UV stable colored quartz aggregates and floor coating resins to achieve proper build and impact resistance.

In general, a high-performance primer is used to ensure proper substrate adhesion followed by multiple layers of broadcast quartz or a quartz slurry matrix. The system is then grouted and top-coated. During the topcoat application, specifiers can determine the traction coefficient suitable for the application. For heavy foot-traffic environments such as interior/exterior breezeways, owners may select a highly textured finish to help prevent slip and fall. For interior decorative applications, a smooth quartz application may be selected to help minimize maintenance.

Decorative Quartz - General 3-Part Specification

Use this generalized Decorative Quartz 3-Part Specification to build a custom Resinwerks Decorative Quartz System. Please consult a Resinwerks technical representative for assistance.

EPX-Q

Heavy-duty double broadcast seamless quartz flooring application. Available with a range of primer options including a vapor barrier epoxy for protection against elevated moisture vapor emission levels. Combines high-quality crystal-clear epoxies with a performance urethane or polyaspartic topcoat for long-term durability.

KTX-Q

A fast-drying double broadcast quartz application that incorporates fast-cure Kinetic® polyaspartic base coats, grout, and topcoats. This system provides for minimal installation down time while providing a UV stable, chemical resistant finish. Available in an unlimited number of colors and blends, the system can be modified to accommodate varying substrate conditions, installation time frames, and coefficient of friction (traction) requirements.

Bio-Cem SLQ

Industrial strength decorative quartz flooring application for ultra-heavy-duty applications. This system incorporates a 1/8” polyurethane concrete slurry primer, followed by a double broadcast quartz. The SLQ system is grouted with a water-clear and chemical resistant 100% solids epoxy and finished with an aggregate fortified high-wear urethane in either a semigloss or satin finish. Available in an unlimited number of colors and blends, this system can be modified to accommodate varying substrate conditions, installation time-frames, and coefficient of friction (traction) requirements.

Quartz System Guide

Seamless quartz flooring systems are an ideal choice for all types of heavy-traffic applications. They offer unique benefits and can be easily modified for texture, color and finish.

Get In Touch Today

Contact us to discuss your application, get samples

or schedule an estimate.