Commercial kitchen flooring works harder than almost any other surface in a facility. Between grease, food spills, heat, water, chemicals, and constant foot traffic, even high-performance flooring systems can wear prematurely if they’re not cleaned and maintained correctly.

This guide is designed to help facility managers and restaurant operators understand how proper restaurant cleaning practices directly impact the longevity, safety, and performance of commercial kitchen floors—especially resinous and seamless systems.

Contents

The Four Biggest Cleaning Hazards for Commercial Kitchen Floors

Best Practices for Daily Restaurant Floor Cleaning

How Often Should Commercial Kitchen Floors Be Professionally Cleaned?

Maximizing the Life Expectancy of Your Commercial Kitchen Floors

Learn More about Commercial Kitchen Flooring and Maintenance

Proper restaurant floor cleaning goes far beyond appearance and sanitation. Over time, improper chemicals, abrasive tools, and poor cleaning habits can lead to costly repairs or premature replacement by:

- Weakening floor coatings

- Reducing slip resistance

- Accelerating wear

Resinous and seamless flooring systems, like those commonly specified for food and beverage environments, are designed to withstand harsh conditions. However, even these systems depend on compatible cleaning methods to maintain their chemical resistance, texture, and structural integrity.

Let's look at some of the most common cleaning practices in commercial and restaurant kitchens that can unintentionally damage flooring systems if done incorrectly.

The Four Biggest Cleaning Hazards for Commercial Kitchen Floors

1. Skipping a Thorough Daily Cleaning

First of all, not being consistent with daily cleaning can actually harm the floor. When dirt and grease are left behind, they act as abrasives under foot traffic. Over time, this dulls floor finishes, breaks down coatings, and increases slip risk. Plus, grease that stays on the floor hardens over time and gets more difficult to remove. Excess soap or improper cleaners can also leave residues that attract even more soil.

Removing grease promptly, using the right kinds of degreasers, is essential to protecting both safety and surface integrity.

2. Using Harsh Cleaning Chemicals and Enzymes

Strong acids, solvents, and high-pH alkaline cleaners can:

- Strip protective coatings

- Weaken resin binders

- Degrade grout and joints

These harsh cleaning products might seem to work well in the short term, but they can prematurely degrade your floors.

Degreasers with enzymes can also cause problems. In some cases, floors exposed to these cleaners can start to deteriorate in just months. Many enzymatic degreasers break down fats by producing oleic acid as a byproduct. Oleic acid has been shown to:

- Rapidly degrade grout

- Compromise certain types of resinous floor coatings

- Cause recurring maintenance and hygiene issues

3. Causing Thermal Shock on Seamless Resinous Floors

Using extremely hot water or steam to disinfect kitchen floors is fairly common. It's quite effective, but the repeated cycling between cold and very hot can cause cracking, peeling, and loose pieces of flooring. The top layer of flooring can expand and contract at a different rate from the subflooring, causing them to pull apart. Make sure you follow the temperature guidelines from the manufacturer of your flooring.

4. Using Aggressive Tools and Equipment

Matching tools and pads to the flooring system is critical. Stiff brushes, abrasive pads, and high-pressure washers can:

- Erode floor coatings

- Polish away slip-resistant, textured surfaces

- Expose underlying layers

The keys are consistency and compatibility, not brute strength.

What Are the Best Practices for Daily Restaurant Floor Cleaning Routines?

Daily cleaning is the single most important factor in extending floor life.

Best practices include:

- Dry sweeping or dust mopping to remove abrasive grit and debris

- Wet cleaning with a pH-neutral commercial kitchen floor cleaner

- Immediate spot cleaning of grease and oil spills

- Thorough rinsing to remove chemical residue

You can find more step-by-step instructions, including how to deal with heavily soiled or stained areas on a resinous floor, in our printable Cleaning and Maintenance Guide.

What Floor Cleaning Chemicals Are Appropriate for Food Service Areas?

In general, for resinous floor coatings, we often recommend a pH-neutral cleaner, such as Simple Green®, diluted with water.

In a food service environment, make sure your floor-cleaning products comply with local health codes and are compatible with your flooring material, such as seamless antimicrobial flooring.

What Cleaning Equipment Should Be Used in Restaurants and Commercial Kitchens?

Professional cleaners typically use nonabrasive equipment to fully remove both soils and cleaning residues. These include microfiber mops, deck brushes with soft bristles, and squeegees.

Examples of appropriate equipment could include:

- Automatic scrubbers with soft pads and recovery tanks

- Wet/dry vacuums

- Low-pressure rinse systems

How Do You Maintain Non-Slip Floors in a Restaurant or Commercial Kitchen?

Non-slip floors rely on surface texture. Maintaining that texture means:

- Avoiding abrasive pads

- Removing grease promptly

- Rinsing thoroughly to prevent buildup of cleaning fluids

Improper cleaning can actually make slip-resistant floors more dangerous over time.

How Often Should Restaurant Floors Be Professionally Cleaned?

While daily cleaning is essential, most restaurant or commercial kitchens benefit from professional cleaning two to four times a year, depending on traffic and exposure.

Professional cleaning helps:

- Remove embedded soils

- Restore surface performance

- Identify early signs of wear

Maximizing the Life Expectancy of Your Commercial Kitchen Floors

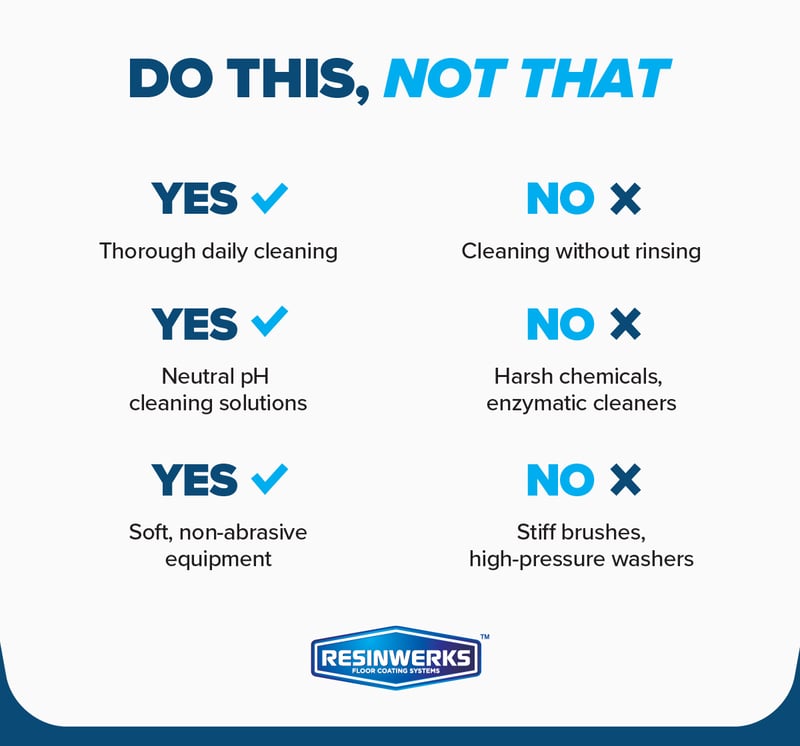

In summary, the keys to maintaining great performance of kitchen flooring over time are:

- Daily, thorough cleaning

- pH-neutral cleaning products

- Non-abrasive cleaning equipment

- Avoiding thermal shock according to manufacturer recommendations

- Quality of the original flooring system

High-performance systems designed for food and beverage environments, when properly maintained, can significantly outlast conventional options.

For instance, the BioCem™ polyurethane concrete system resists damage from both enzymatic cleaners and thermal shock, making it a good choice for commercial kitchen flooring. It's widely used in restaurants, breweries, and food and beverage manufacturing.

When Should Commercial Kitchen Floors Be Replaced?

Early intervention can sometimes prevent full replacement. Warning signs that you shouldn't ignore include:

- Persistent staining

- Loss of slip resistance

- Cracking, peeling, or discoloration

- Increased cleaning difficulty

Although proactive cleaning and maintenance can delay this point significantly. Replacement may be necessary when:

- Structural integrity is compromised

- Slip resistance cannot be restored

- Hygiene standards can no longer be met

Learn More About Commercial Kitchen Flooring and Maintenance

Download our Food and Beverage Flooring Guide for details including:

- Design Considerations

- Curtailing Bacteria Growth

- Thermal Shock Implications

- Maintenance & Long-Term Durability

- Benefits of Polyurethane Concrete for Food and Beverage Flooring